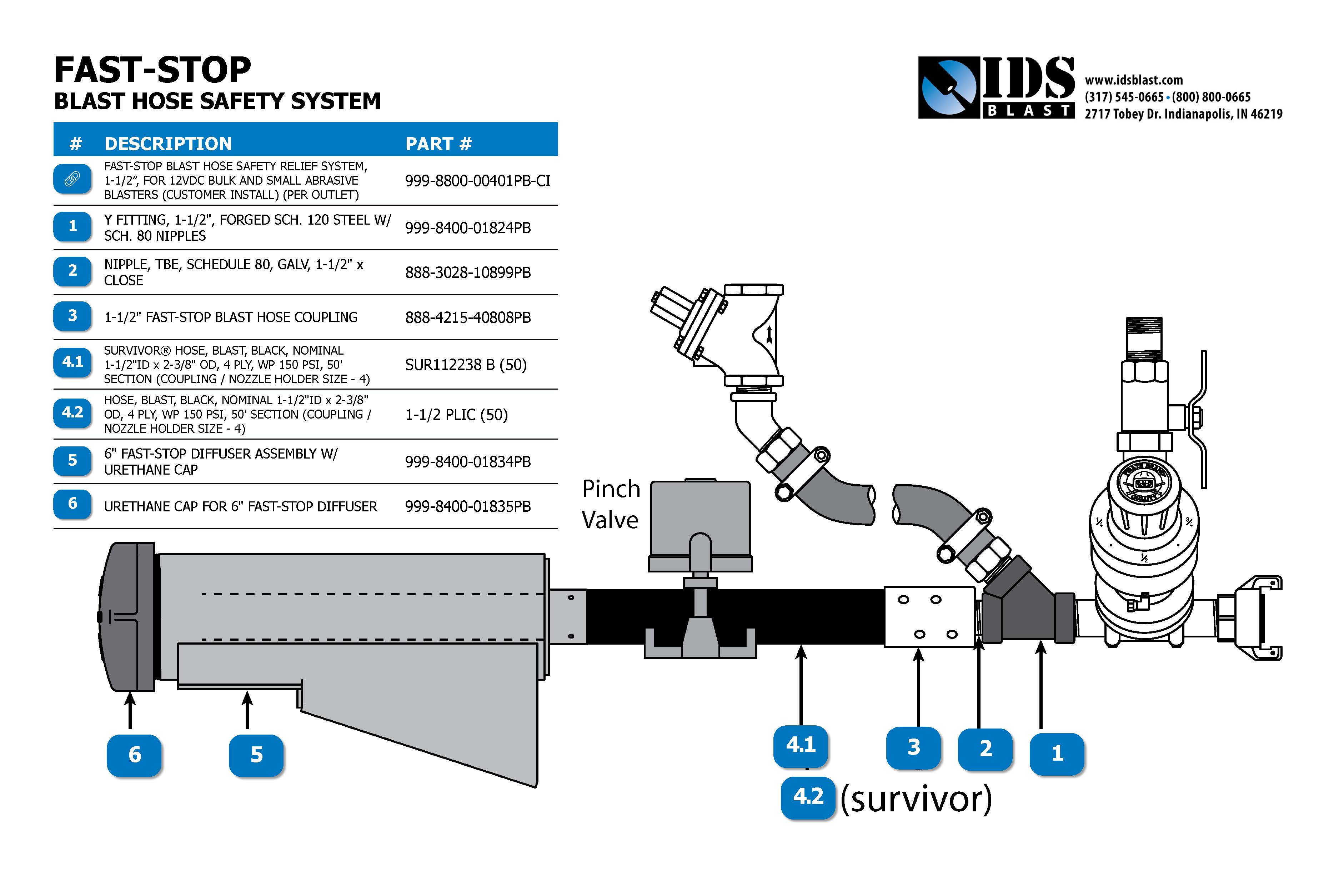

FAST-STOP BLAST HOSE SAFETY RELIEF SYSTEM, 1-1/2", FOR 12VDC BULK AND SMALL ABRASIVE BLASTERS (CUSTOMER INSTALL) (PER OUTLET)

This product is compatible with the following OEM manufacturers

IDS Blast is an authorized distributor of Pirate Brand®, RPB Safety®, Bullard®, Blast-It-All®, Trinco™ & Graco®.

We are not an authorized distributor of the other manufacturers listed above.

The Fast-Stop™ Blast Hose Safety System is available Factory Installed on SPH Bulk Blasters, 6.5, 10 & 20 cu ft abrasive blasters with electric controls. Customer installable kits are sold per outlet and require a SPH System with electric controls in good working order. Customer is to supply and install a suitable mounting platform for customer installed systems. Please contact a qualified Pirate Brand® representative prior to installing a Fast-Stop™ kit to make sure the abrasive blaster is safe to use as a Fast-Stop™ system. WARNING: It is dangerous to install a Fast-Stop™ kit on an abrasive blaster it is not designed to work with.

The Pirate Brand® Fast-Stop™ System provides additional operator safety by drastically reducing the time it takes for the blast hose to depressurize after the control handle is released. This results in reduced whipping of the blast hose should the operator lose their grip and drop the control handle & hose. Since the Fast-Stop™ exhausts from the opposite end of the blast hose, it has the added safety of being able to depressurize the system even when an obstruction jams in the nozzle throat or a piece of heavy equipment parks on the blast hose. In a standard system, pressurized air would be trapped between the obstruction and the pressure vessel and be released unexpectedly when the nozzle is removed or the piece of equipment moves off of the blast hose. All of this is accomplished by the Fast-Stop™ System using simple components and a reliable design ensuring your system will last long and work when you need it to.