There are no products listed under this category.

CONTROLS

What type of controls are appropriate to your applications? Do you prefer pneumatic, or do you work in cold weather or have long blast hose runs and need electric controls? Do you need abrasive cut-off controls to blow off your project with clean compressed air? We do it all.

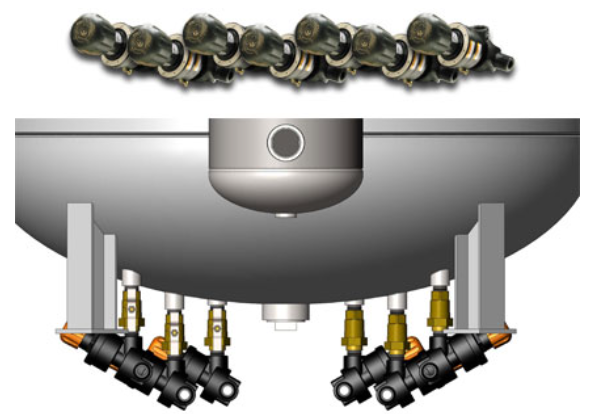

METERING VALVES

You also have options when it comes to metering valves. We recommend the tried-and-true APVII™ (Automatic Plunger Valve) with solid tungsten carbide sleeve. Other choices include the APV, or go old school and pair an MPV, MPVII™ (Manual Plunger Valve) or #100 Metering valve with a Pinch Valve.

OUTLETS

How many outlets should a bulk blaster have? You tell us. From 1 outlet up to 16, if it is possible, we will supply it the way you need it.

CLOSURES

You have options when it comes to the bulk pot top closure. There is the standard 10” 5-Bolt Cam-Lock closure, the larger 16” 7-Bolt Cam-Lock closure, and now for automatic filling, a funnel fill system with a Posi-Seal valve, umbrella, and burp bag. The Posi-Seal Valve is like a pneumatically controlled pop-up which seals the pressure vessel allowing it to pressurize. The standard 10” closure is available with the Posi-Seal valve for added safety.

INLET

Whether you want the added protection of a moisture separator or just want a simple manifold, we will build your bulk pot just the way you need it. You may also opt for a larger BIG GUN™ ground joint coupling at the compressed air connection for the best possible flow from the compressor.

POSI SEAL SAFETY SYSTEM

Safety is always a concern when sandblasting. The Pirate Brand® Posi Seal Safety System keeps the top closure sealed until the vessel is depressurized preventing injury from opening a pressurized bulk blaster.

• HUMAN ERROR PROOF: Requires no action or knowledge from the operators to keep the top closure sealed while the bulk blaster is pressurized. The most common cause of top closure injury is operator error.

• FULLY AUTOMATIC: Seals when pressurized

• SAFEST OPTION for bulk blaster injury prevention available

PIPING

How your bulk pot is piped will greatly influence your productivity. If your piping is restrictive then blasting will be less efficient. This is why all Pirate Brand® bulk pots come standard with 1-1/2” piping. For the best possible productivity, choose the BIG GUN™ Full Flow system which includes larger air valves.

MOUNTINGS

Highway Trailers, Yard Trailers, Skids with Fork Pockets & Custom Length Stationary Legs are some of your options for mounting your bulk blaster. Wherever your bulk pot needs to go, mobile or stationary, we have a solution.

LOCK-OUT TAG-OUT

Closes and locks over the cam-lock closure preventing unauthorized or untrained personnel from accessing the bulk blaster top closure. Includes an attachment cable so it won’t fall off the bulk pot when opened. (Available for 10” and 16” Closures)

FAST-STOP SYSTEM™

The Pirate Brand® Fast-Stop™ System provides additional operator safety by drastically reducing the time it takes for the blast hose to depressurize after the control handle is released. This results in reduced whipping of the blast hose should the operator lose their grip and drop the control handle & hose. Since the Fast-Stop™ exhausts from the opposite end of the blast hose, it has the added safety of being able to depressurize even when the nozzle is obstructed or the blast hose is pinched.

CUSTOM COATINGS

Want your bulk blasting equipment in your company colors? Or maybe a specific type of urethane top coating? Need an epoxy lined interior for your bulk pots? Whatever your needs, we will work to make it happen. At our facility we can do just about anything.

OFF-SHORE SYSTEMS™

Off Shore™ Bulk Pots are tough enough for the most harsh conditions on the planet. They feature an extreme coating system on the interior and exterior for the highest durability in the toughest environmental conditions.

• SePCo / BHP Packages Available

• Cable Sling & Shackle Package Available

BULK ABRASIVE

The point of a bulk blaster is to blast with a high capacity for abrasive. Pirate Brand® has 2 solutions that can make refilling that high capacity pressure vessel faster and much more convenient.

ABRASIVE STORAGE HOPPER: The 725 cu ft abrasive media storage hopper by Pirate Brand® is the perfect solution for quick loading of abrasive into small or bulk blasting equipment. Hopper Pad Eye Design & Structural Analysis Report Certified By Registered Professional Engineer in Mechanical Engineering.

BULK BAG RACK: Our bulk bag rack mounts directly to ports in the top of our bulk blasters. It holds a standard bulk bag of media for easier filling.

CUSTOM FABRICATION

Any type of custom fabrication can be achieved to fully meet your specific needs.

Spend more time blasting and less time dealing with all the little things required to get started. Just roll into the job site, connect your blast hoses and go to work! Air Compressors, Air Dryer, Blast Pots, Breathing Air Filtration – ALL READY TO GO.

WORK PLATFORMS

Mounted in the bulk bag rack ports, we can custom fabricate a work platform allowing workers to access the top of the bulk blaster with ease.

*Not all combinations of features listed above are possible. Custom orders may be subject to

Additional Fees / Order Minimums / Longer Lead Times on a case-by-case basis.